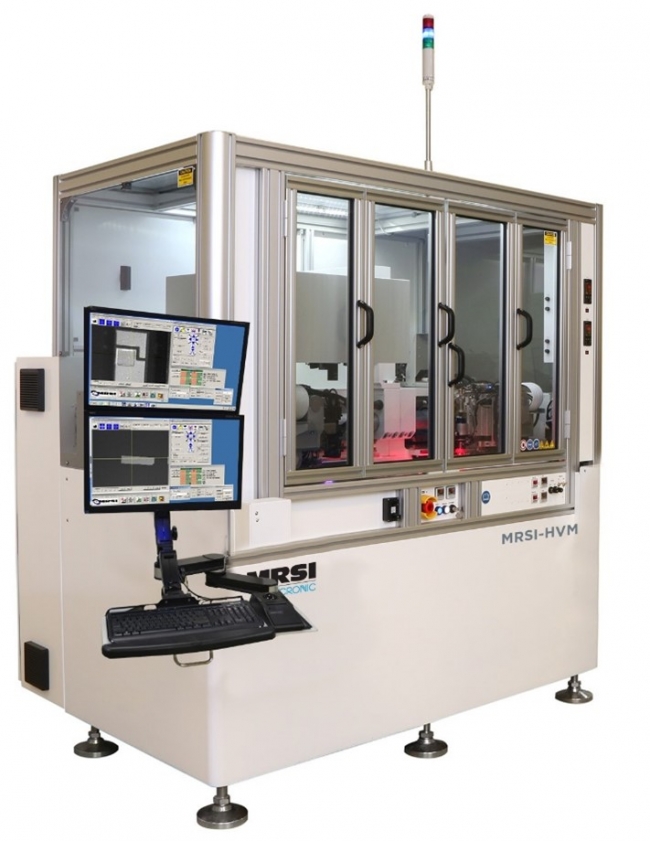

Home > SEMICONDUCTOR > Micron Flip-Chip DIE BONDERS > MRSI-HVM FAMILY 1.5-MICRON DIE BONDERS -

MRSI-HVM系列: 高速、靈活的1.5微米黏晶機,適應大批量生產

Micron Flip-Chip DIE BONDERS

MRSI-HVM FAMILY 1.5-MICRON DIE BONDERS -

MRSI-HVM系列: 高速、靈活的1.5微米黏晶機,適應大批量生產

Benefits of MRSI-HVM Family

The MRSI-HVM product family has proved to be the best-in-class die bonder with the leading speed﹐ zero-time tool change between dies﹐ and <1.5 micron accuracy. The superior performance is enabled by dual head﹐ dual stage﹐ integrated “on-the-fly” tool changer﹐ ultrafast eutectic stage﹐ and multi-levels of parallel processing optimizations.

The MRSI-HVM is designed for specific applications including Chip-on-Carrier (CoC)﹐ Chip-on-Submount (CoS)﹐ and Chip-on-Baseplate (CoB) assembly using eutectic and/or epoxy stamping die bonding.

The MRSI-HVM with conveyor is equipped with inline conveyor for single fixture or multiple cassette inputs that can automatically transport large forms of carriers of the dies for Active Optical Cables (AOC) or similar chip-on-printed circuit board (PCB) applications﹐ gold-box packaging﹐ and CoC in fixture. The process choices include eutectic﹐ epoxy stamping﹐ UV epoxy dispensing﹐ and in-situ UV curing.

The heated head version includes a heated head on the right side while the left side still has the same head as a typical MRSI-HVM. The localized top heating at a fixed temperature or with pulsed heating is specially designed for eutectic bonding of multiple dies onto a common carrier without reflowing the neighboring solder pads.

MRSI-HVM系列的優勢

MRSI-HVM產品系列以其領先的速度,吸嘴間的“零時間”切換和小於1.5微米貼片精度被公認為業界領先的一流黏晶機。其雙機頭、雙共晶焊接台、“零時間”吸嘴轉換系統的配置,超快速共晶焊接溫度的升降以及多層次多功能並行工藝自動化處理﹐實現了MRSI-HVM產品系列卓越的性能。

MRSI-HVM專為特定應用而設計,包括使用共晶和/或蘸膠工藝的CoC封裝、CoS封裝和CoB封裝。

傳送帶版本 – MRSI-HVM配備用於單個夾具或多盤輸入的內聯式傳送機,可以自動的大量輸送針對有源光纜(AOC)或晶片到印刷電路板(PCB)這類應用、以及管盒封裝(Gold-box)及在夾具中的CoC等多種晶片載體。工藝流程可選擇包括共晶焊接、環氧蘸膠粘結、UV環氧點膠和原位UV固化。

熱頭版本 – MRSI-HVM右側包括一個加熱頭,而左側與標準MRSI-HVM具有相同的頭。右側加熱頭以固定溫度對頂部進行小範圍加熱,或使用專為多晶片共晶焊而設計的脈衝加熱,以便將多個晶片粘貼在同一個基板上而不會回流鄰近焊料。

The MRSI-HVM product family has proved to be the best-in-class die bonder with the leading speed﹐ zero-time tool change between dies﹐ and <1.5 micron accuracy. The superior performance is enabled by dual head﹐ dual stage﹐ integrated “on-the-fly” tool changer﹐ ultrafast eutectic stage﹐ and multi-levels of parallel processing optimizations.

The MRSI-HVM is designed for specific applications including Chip-on-Carrier (CoC)﹐ Chip-on-Submount (CoS)﹐ and Chip-on-Baseplate (CoB) assembly using eutectic and/or epoxy stamping die bonding.

The MRSI-HVM with conveyor is equipped with inline conveyor for single fixture or multiple cassette inputs that can automatically transport large forms of carriers of the dies for Active Optical Cables (AOC) or similar chip-on-printed circuit board (PCB) applications﹐ gold-box packaging﹐ and CoC in fixture. The process choices include eutectic﹐ epoxy stamping﹐ UV epoxy dispensing﹐ and in-situ UV curing.

The heated head version includes a heated head on the right side while the left side still has the same head as a typical MRSI-HVM. The localized top heating at a fixed temperature or with pulsed heating is specially designed for eutectic bonding of multiple dies onto a common carrier without reflowing the neighboring solder pads.

MRSI-HVM系列的優勢

MRSI-HVM產品系列以其領先的速度,吸嘴間的“零時間”切換和小於1.5微米貼片精度被公認為業界領先的一流黏晶機。其雙機頭、雙共晶焊接台、“零時間”吸嘴轉換系統的配置,超快速共晶焊接溫度的升降以及多層次多功能並行工藝自動化處理﹐實現了MRSI-HVM產品系列卓越的性能。

MRSI-HVM專為特定應用而設計,包括使用共晶和/或蘸膠工藝的CoC封裝、CoS封裝和CoB封裝。

傳送帶版本 – MRSI-HVM配備用於單個夾具或多盤輸入的內聯式傳送機,可以自動的大量輸送針對有源光纜(AOC)或晶片到印刷電路板(PCB)這類應用、以及管盒封裝(Gold-box)及在夾具中的CoC等多種晶片載體。工藝流程可選擇包括共晶焊接、環氧蘸膠粘結、UV環氧點膠和原位UV固化。

熱頭版本 – MRSI-HVM右側包括一個加熱頭,而左側與標準MRSI-HVM具有相同的頭。右側加熱頭以固定溫度對頂部進行小範圍加熱,或使用專為多晶片共晶焊而設計的脈衝加熱,以便將多個晶片粘貼在同一個基板上而不會回流鄰近焊料。