Home > SEMICONDUCTOR > Micron Flip-Chip DIE BONDERS > MRSI-M3 3-MICRON FLIP-CHIP DIE BONDER - 3微米覆晶黏晶機

Micron Flip-Chip DIE BONDERS

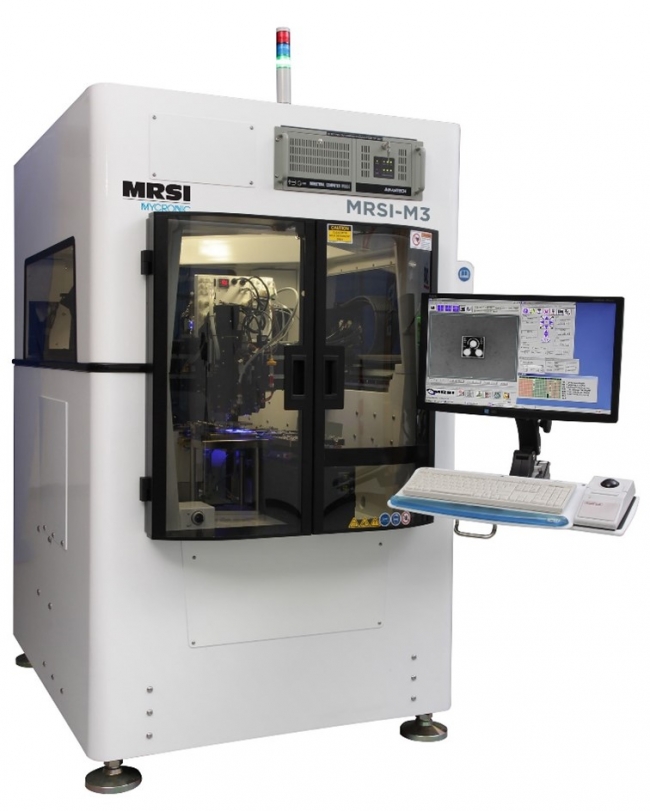

MRSI-M3 3-MICRON FLIP-CHIP DIE BONDER - 3微米覆晶黏晶機

The MRSI-M3 3-Micron Flip-chip Die Bonder sets the industry standard for ultra-precision﹐ high-complexity die attach in high volume production environments. With features such as force control﹐ ultra precise placements﹐ and 360° die orientation﹐ the MRSI-M3 die bonder ensures high yields﹐ high quality and high reliability in advanced packaging.

The highly configurable﹐ MRSI-M3 platform ensures optimum asset protection. The system delivers an unmatched combination of 3-micron accuracy﹐ automation﹐ speed and reliability﹔ in-situ assembly processes such as eutectic die bonding﹐ UV epoxy die attach and flip chip assembly are all possible. The MRSI-M3 3-Micron die bonder is ideally suited for manufacturers of microwave modules﹐ IR sensors﹐ MEMS﹐ multi-chip modules﹐ stacked assemblies﹐ hybrid devices and photonic packages.

From small dies to large sensors﹐ the MRSI-M3 3-Micron die bonder provides all the capability and flexibility to assemble the most advanced packages﹐ without compromising on manufacturing efficiency﹐ quality and reliability.

Benefits

The MRSI-M3 uses an advanced cast composite base﹐ enabling fast and accurate moves with virtually no settling time. The large work envelope enables a wide range of configurations (see options tab) to meet customer requirements.

Advanced functionality equates to significant benefits:

• High Speed AND High Accuracy – An advanced axis system driven by brushless DC linear servomotors with linear glass-scale encoder feedback for high speeds and accurate movements.

• High Machine Efficiency AND High Product Quality – Built-in internal temperature monitoring ensures consistent placement. Known heat sources﹐ such as motors are designed with gas cooling﹔ ensuring that thermal expansion is kept to a minimum.

• Optimum Placement Yields – The system’s closed-loop force control enables placement of delicate Gallium Arsenide (GaAs) dies with as little as 10 grams of force. At the other end of the scale﹐ forces up to 2kg are programmable.

• Flexible Component Supply Options – Die are picked from waffle pack﹐ Gel-Pak®﹐ wafer﹐ tape and reel and custom trays.

• Maximum Asset Use – MRSI-M3 machines are designed to handle a wide range of processes. Epoxy dispensing pumps﹐ epoxy stamping and eutectic bonding with scrub and temperature control﹐ are all configuration options that make the MRSI-M3 3-micron die bonder a complete assembly solution (see features tab for details).

MRSI-M3 3微米覆晶黏晶機,為大批量生產環境下的超高精度、高複雜性晶片貼裝樹立了標杆。MRSI-M3 覆晶黏晶機通過貼片壓力控制、超高精度貼放以及360°晶片定向等特性,確保了先進封裝過程中的高良率、高品質和高可靠性。

高度可自由配置的 MRSI-M3 平臺,使資產得到最優的保值。該系統集合了3微米精度、自動化、速度和可靠性等特點,是其它設備無可比擬的;諸如共晶焊、紫外環氧貼片以及倒裝晶片裝配等原位裝配過程都可以實現。MRSI-M3 3微米覆晶黏晶機是微波模組、紅外感測器、微電子機械系統 (MEMS)、多晶片模組、堆疊式組裝、混合器件和光電子封裝等製造商的理想產品。

從細小的晶片到寬大的感測器,MRSI-M3 3微米覆晶黏晶機能夠為最先進封裝提供靈活而多樣的封裝能力,而且不會降低生產效率、品質和可靠性。

優點

MRSI-M3 採用先進的鑄造聚合物基座,使高速而精確的運動成為可能,且幾乎沒有停滯時間。超大的工作空間,可根據客戶需求進行各種配置(參見選配功能標籤)

與重大優點相當的先進功能:

高速及高精度– 配備一套先進的由無刷直流線性伺服電機驅動的軸系統,附帶直線光柵尺編碼器回饋,保證高速度精確的運動。

高設備效率及高產品品質– 內置的內部溫度監測確保了貼放的一致性。為電機等已知熱源設計了氣體冷卻;確保熱膨脹維持在最低限度。

最優的貼放良率– 系統的閉環壓力控制功能可使貼放壓力低至10克,對易碎的砷化鎵 (GaAs) 晶片進行貼放。反之,可程式設計設置將貼放力提高到2千克。

供料選項多樣– 可從華夫盤 (waffle pack)、Gel-Pak™、晶圓、帶料、卷料和定制料盤上拾取晶片。

資產利用最大化MRSI-M3 機台的設計可處理多種工藝。環氧點膠泵、環氧蘸膠及帶刮擦和溫度控制的共晶焊等選配功能令MRSI-M3 3微米覆晶黏晶機自成一整套組裝解決方案。

The highly configurable﹐ MRSI-M3 platform ensures optimum asset protection. The system delivers an unmatched combination of 3-micron accuracy﹐ automation﹐ speed and reliability﹔ in-situ assembly processes such as eutectic die bonding﹐ UV epoxy die attach and flip chip assembly are all possible. The MRSI-M3 3-Micron die bonder is ideally suited for manufacturers of microwave modules﹐ IR sensors﹐ MEMS﹐ multi-chip modules﹐ stacked assemblies﹐ hybrid devices and photonic packages.

From small dies to large sensors﹐ the MRSI-M3 3-Micron die bonder provides all the capability and flexibility to assemble the most advanced packages﹐ without compromising on manufacturing efficiency﹐ quality and reliability.

Benefits

The MRSI-M3 uses an advanced cast composite base﹐ enabling fast and accurate moves with virtually no settling time. The large work envelope enables a wide range of configurations (see options tab) to meet customer requirements.

Advanced functionality equates to significant benefits:

• High Speed AND High Accuracy – An advanced axis system driven by brushless DC linear servomotors with linear glass-scale encoder feedback for high speeds and accurate movements.

• High Machine Efficiency AND High Product Quality – Built-in internal temperature monitoring ensures consistent placement. Known heat sources﹐ such as motors are designed with gas cooling﹔ ensuring that thermal expansion is kept to a minimum.

• Optimum Placement Yields – The system’s closed-loop force control enables placement of delicate Gallium Arsenide (GaAs) dies with as little as 10 grams of force. At the other end of the scale﹐ forces up to 2kg are programmable.

• Flexible Component Supply Options – Die are picked from waffle pack﹐ Gel-Pak®﹐ wafer﹐ tape and reel and custom trays.

• Maximum Asset Use – MRSI-M3 machines are designed to handle a wide range of processes. Epoxy dispensing pumps﹐ epoxy stamping and eutectic bonding with scrub and temperature control﹐ are all configuration options that make the MRSI-M3 3-micron die bonder a complete assembly solution (see features tab for details).

MRSI-M3 3微米覆晶黏晶機,為大批量生產環境下的超高精度、高複雜性晶片貼裝樹立了標杆。MRSI-M3 覆晶黏晶機通過貼片壓力控制、超高精度貼放以及360°晶片定向等特性,確保了先進封裝過程中的高良率、高品質和高可靠性。

高度可自由配置的 MRSI-M3 平臺,使資產得到最優的保值。該系統集合了3微米精度、自動化、速度和可靠性等特點,是其它設備無可比擬的;諸如共晶焊、紫外環氧貼片以及倒裝晶片裝配等原位裝配過程都可以實現。MRSI-M3 3微米覆晶黏晶機是微波模組、紅外感測器、微電子機械系統 (MEMS)、多晶片模組、堆疊式組裝、混合器件和光電子封裝等製造商的理想產品。

從細小的晶片到寬大的感測器,MRSI-M3 3微米覆晶黏晶機能夠為最先進封裝提供靈活而多樣的封裝能力,而且不會降低生產效率、品質和可靠性。

優點

MRSI-M3 採用先進的鑄造聚合物基座,使高速而精確的運動成為可能,且幾乎沒有停滯時間。超大的工作空間,可根據客戶需求進行各種配置(參見選配功能標籤)

與重大優點相當的先進功能:

高速及高精度– 配備一套先進的由無刷直流線性伺服電機驅動的軸系統,附帶直線光柵尺編碼器回饋,保證高速度精確的運動。

高設備效率及高產品品質– 內置的內部溫度監測確保了貼放的一致性。為電機等已知熱源設計了氣體冷卻;確保熱膨脹維持在最低限度。

最優的貼放良率– 系統的閉環壓力控制功能可使貼放壓力低至10克,對易碎的砷化鎵 (GaAs) 晶片進行貼放。反之,可程式設計設置將貼放力提高到2千克。

供料選項多樣– 可從華夫盤 (waffle pack)、Gel-Pak™、晶圓、帶料、卷料和定制料盤上拾取晶片。

資產利用最大化MRSI-M3 機台的設計可處理多種工藝。環氧點膠泵、環氧蘸膠及帶刮擦和溫度控制的共晶焊等選配功能令MRSI-M3 3微米覆晶黏晶機自成一整套組裝解決方案。